In 2026, infection control stands out as the most important factor when dental offices buy or update equipment. The dental chair serves as the main piece in every treatment room. It also has the longest patient contact time and the biggest chance for cross-contamination. Modern chairs built around disinfection are not just nice to have anymore. They have become a basic need for keeping patients safe, protecting staff, meeting rules, and keeping a good name for the practice over time.

Most older-style dental chairs still sold these days first appeared between the 1990s and early 2010s. Back then, companies cared more about strong mechanics, patient comfort, and lower prices instead of serious infection prevention.

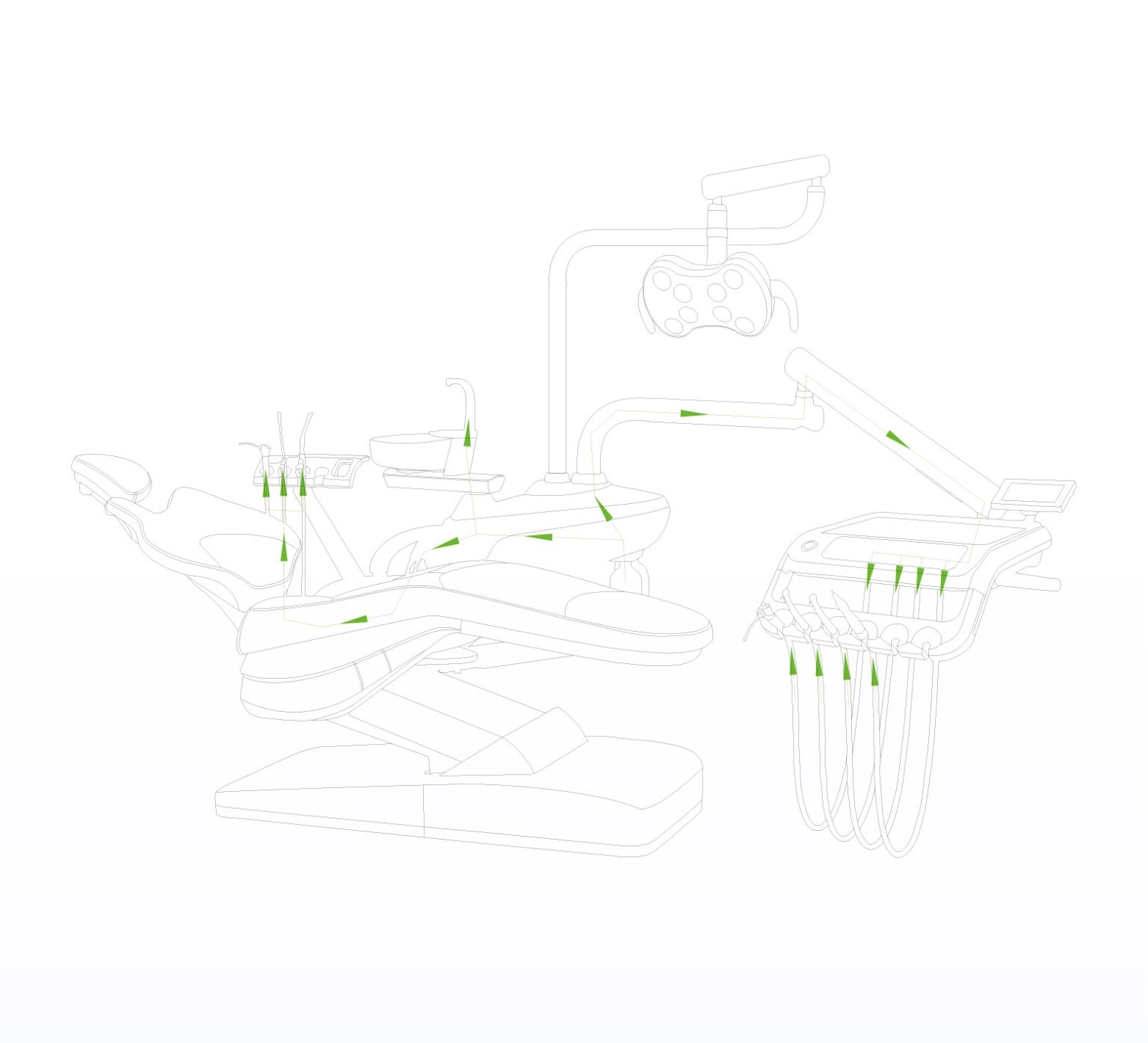

Common risky spots include:

Several separate studies from 2020 to 2025 keep finding these areas test positive for:

Aerosol-producing treatments, lots of touched surfaces, and not enough cleaning time between patients create perfect conditions for germs to stay and spread.

Top manufacturers have answered with complete automatic disinfection dental chairs. These handle both outside surfaces and inside fluid paths at the same time.

The most up-to-date systems in 2025–2026 models usually contain:

Some leading Chinese manufacturers now provide models that reach >99.999% reduction of common oral germs in internal lines after a normal 5-minute cycle (checked and confirmed by third-party labs).

Besides automatic features, material choices have changed a lot:

| Feature | Traditional Chairs (pre-2020) | Current Premium Hygienic Chairs (2025–2026) |

|---|---|---|

| Upholstery | Standard PU leather, often porous | Medical-grade seamless PU or nano-silver composite |

| Seam design | Multiple stitched seams | Almost completely seamless or welded edges |

| Armrest & headrest | Textured plastic, many gaps | Smooth, one-piece molded with antimicrobial additive |

| Frame & base coating | Standard powder coat | Nano-antimicrobial powder coat or stainless steel |

| Touch surfaces | Ordinary ABS plastic | Silver-ion / copper-ion infused polymers |

These better materials, when used with proper hospital-grade surface disinfectants, can cut surface germs by 3–4 log₁₀ in just 30 seconds of wiping.

Big rule-making groups have raised standards step by step:

Patients have also changed their views. Surveys done in North America, Europe, and Asia between 2024–2025 show 78–86% of people now carefully look at and judge how clean the treatment room appears — and the dental chair catches their eye the most.

In 2026, the question is no longer if a practice should choose a chair with good disinfection features. Now the real question is which level of disinfection technology gives the best mix of patient safety, smooth daily work, and reasonable total cost.

Gladent has placed itself at the front of this change. The company combines full-pipeline automatic disinfection, medical-grade seamless surfaces, silver-ion antimicrobial technology, and easy one-touch controls across several series (especially the flagship GD-S800 and the new 2026 GD-S900 Pro).

As a professional Chinese manufacturer, supplier and factory, Gladent welcomes distributors, group practices, hospital chains, and dental equipment dealers to experience the current generation of hygienic engineering.

Most current advanced systems recommend 3–6 minutes for standard inter-patient disinfection; sufficient for >5 log reduction of common oral pathogens when using validated disinfectants.

Yes — automatic pipeline disinfection handles internal lines, but external high-touch surfaces still require manual wiping with EPA/List N or equivalent disinfectants.

CDC recommends periodic monitoring (frequency depends on treatment volume); many advanced practices now test monthly when using automatic disinfection systems.

In most cases no — effective whole-pipeline disinfection requires specially designed internal plumbing, independent disinfectant bottles, and compatible control software.

In the current market (2026), advanced disinfection features usually add 12–28% to the base price of mid-range to premium chairs.

Dental equipment distributors, large group practices, hospital purchasing departments, and turn-key clinic developers are invited to cooperate with Gladent — a specialized Chinese manufacturer, supplier and factory with strong export experience.

We offer:

• Full-pipeline automatic disinfection models (GD-S800 / GD-S900 series)

• Competitive factory-direct pricing with stable quality

• CE, ISO 13485 certification

• Flexible OEM/ODM services

• Fast 30–45 day production lead time

Contact the Gladent international team today for latest 2026 catalog, disinfection validation reports, and quotation.

Email: gladent08@dental-chair.cn

Tel / WhatsApp: +86 13543616157

Official website: https://www.dental-unit.net/